Some examples of the areas of application of technical fabrics:

Membranes and seals

One of the main areas of application of technical fabrics is membranes and seals, which are used for roofing, waterproofing, geomembranes and expansion joints. These applications require fabrics that are resistant to water, weather, chemicals and mechanical stress. Some of the fabrics used for this purpose are polyester, polyamide, polyethylene, polypropylene and polyvinyl chloride. The fabrics are usually coated or laminated with polymer-based mixes to increase their strength, adhesion and resistance.

Outdoor fabrics

Another area of application of technical fabrics is outdoor fabrics, which are used for tents, awnings, canopies and boat covers. These applications require fabrics that are light, durable, breathable and UV-resistant. Some of the fabrics used for this purpose are nylon, polyester, acrylic and cotton. The fabrics are often dyed or printed to give them colour or patterns according to customer preferences or standards. They may also undergo functional finishing to add special features such as water repellency, flame retardancy or antimicrobial activity.

Protective clothing fabrics

A third area of application is protective clothing fabrics, which are used for fire-fighters, military personnel and industrial workers. These applications require fabrics that are flame-resistant, heat-resistant, cut-resistant and abrasion-resistant. Some of the fabrics used for this purpose are para-aramydic, meta-aramydic, modacrylic and glass fibers. The fabrics are usually woven or knitted in specific structures to provide protection and comfort. They may also be treated with chemicals or coatings to improve their performance.

Conveyor belts fabrics

A fourth area of application is conveyor belts fabrics, which are used for mining, cement, food and textile industries. These applications require fabrics that are strong, flexible and resistant to wear and tear. Some of the fabrics used for this purpose are polyester, polyamide and cotton. The fabrics are usually woven in plain or twill structures to provide stability and grip. They may also be heat set or sanforized to prevent shrinkage or distortion during use or washing.

High performance fabrics

A fifth area of application is high performance fabrics, which are used for aerospace, marine, sports and medical applications. These applications require fabrics that have exceptional properties such as high strength-to-weight ratio, high modulus of elasticity, high impact resistance and biocompatibility. Some of the fabrics used for this purpose are carbon fibers, aramid fibers, polyethylene fibers and polyurethane fibers. The fabrics are usually produced by advanced techniques such as spinning, weaving, knitting or nonwoven processes to achieve the desired characteristics.

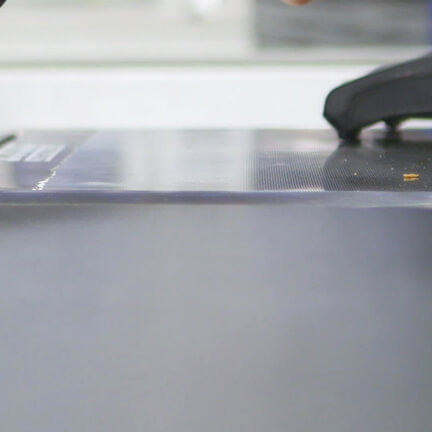

Offset printing and digital printing fabrics

A seventh area of application of technical fabrics is offset printing and digital printing fabrics, which are used for lithographic printing blankets in the offset and digital printing industry. These applications require fabrics that have high dimensional stability, high tensile strength and high adhesion with polymer-base mixes. Some of the fabrics used for this purpose are polyester, cotton and nylon. The fabrics are usually woven in medium high counts to guarantee technical properties.

Filtration, packaging, insulation and reinforcement

An eighth area of application is industrial fabrics, which are used for filtration, packaging, insulation and reinforcement. These applications require fabrics that have specific properties such as porosity, permeability, thermal conductivity and mechanical resistance. Some of the fabrics used for this purpose are polyester, polyamide, polypropylene and glass fibers. The fabrics are usually produced by weaving, knitting or nonwoven processes to provide the required structure and function.

ITA

ITA DE

DE